Drive-In Racking Product Overview

Drive-in pallet racking is best for storage of large, heavyweight volumes of items with a low quantity of different items. The storage concentration advantage of this racking makes pallets stored without aisles for remarkably dense storage.

- Thorough control of entrances and exits.

- Allows many SKU as load lanes.

- Efficient and safe block stacking unstable and fragile loads.

About Drive-In Racking

Find out if this system is right for your business or operation

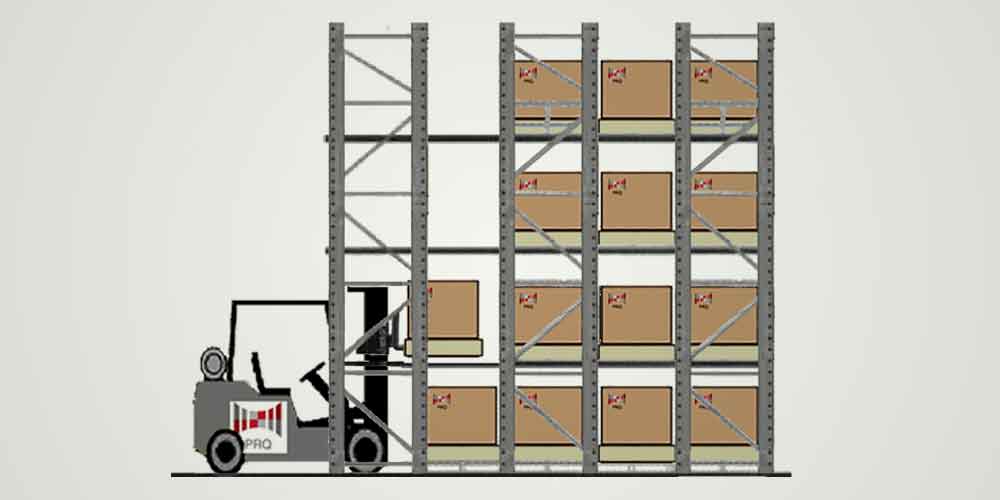

Load units are typically stored on the racking depth one behind the other on two continuous beams when a drive-in/drive through racking system is applied in one’s warehouse. It follows the “accumulation principle” for storage, enabling the highest use of existing space in terms of height and area. Following the principle makes the drive-in racking the best for elimination of aisles between shelves and admission of many references as load lanes.

A certain cycle per racking from bottom to top (or vice versa) must be observed strictly when one is stacking or retrieving. The purpose of this is to give opportunity to fork lift trucks to drive into the racking bays. With this racking type, pallets are stacked by the first-in, last out (FILO) method on supports mounted on the sides of the drive-in channels. Thus, individual pallets can only be accessed one by one from the front of the rack.

The block stacking characteristic of drive-in racking considerably increases the density of storage in a warehouse. Accordingly, the available space is subjected to up to 90% more effectivity than the conventional pallet storage systems.